Innovative solutions and packages designed and crafted to increase industry efficiencies.

Our Divisions

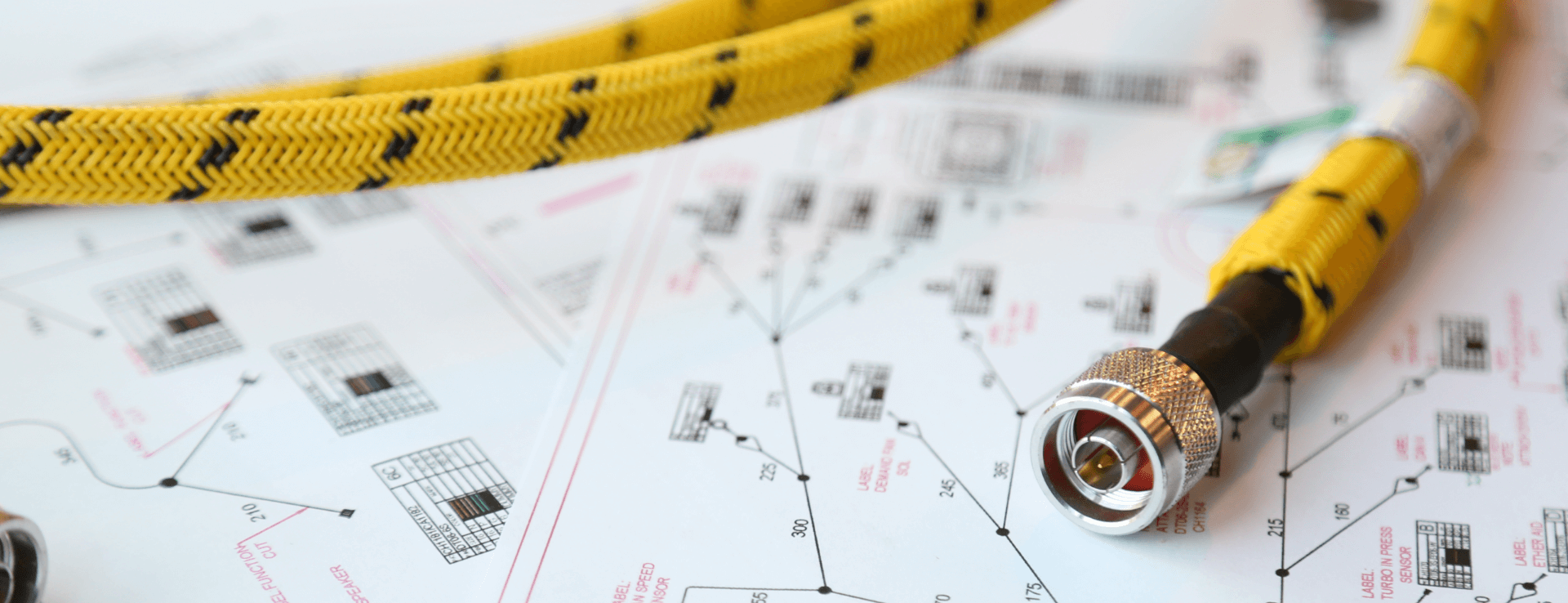

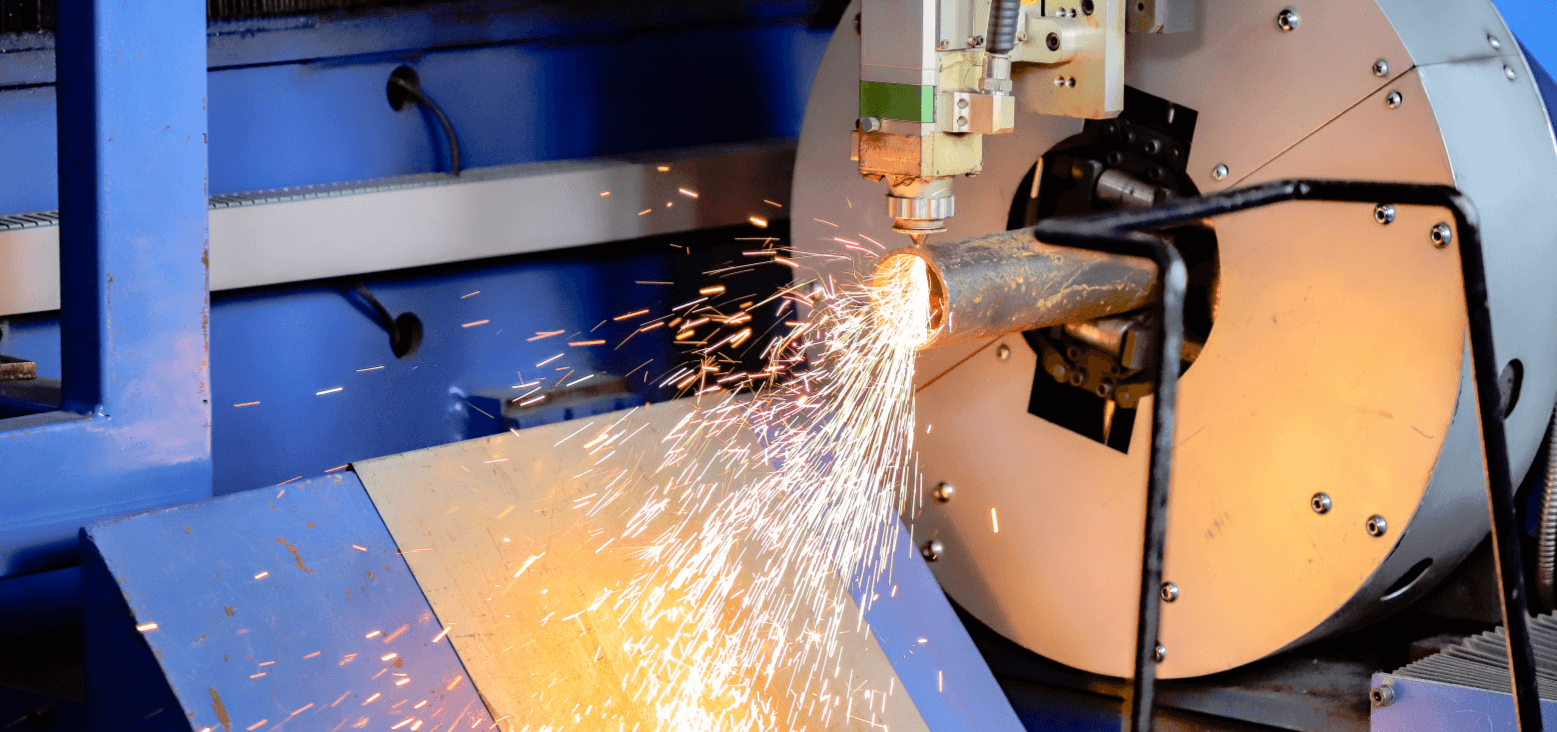

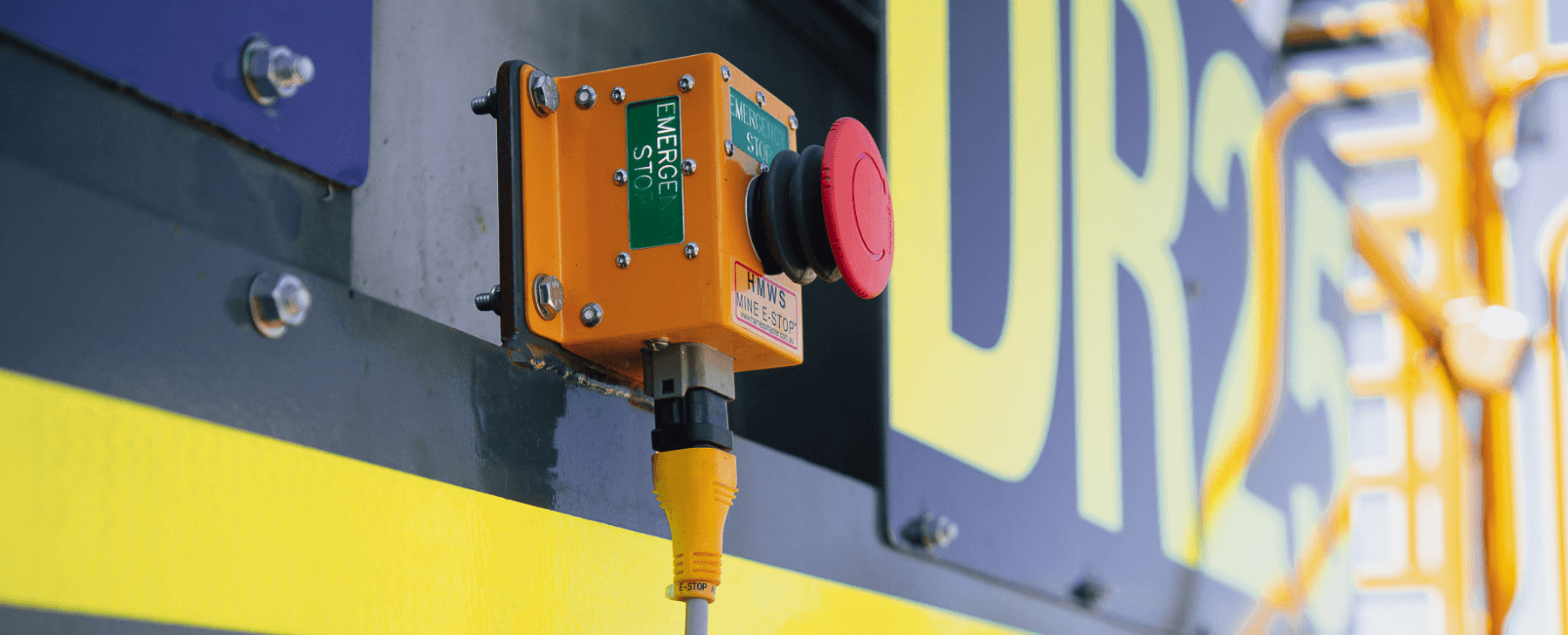

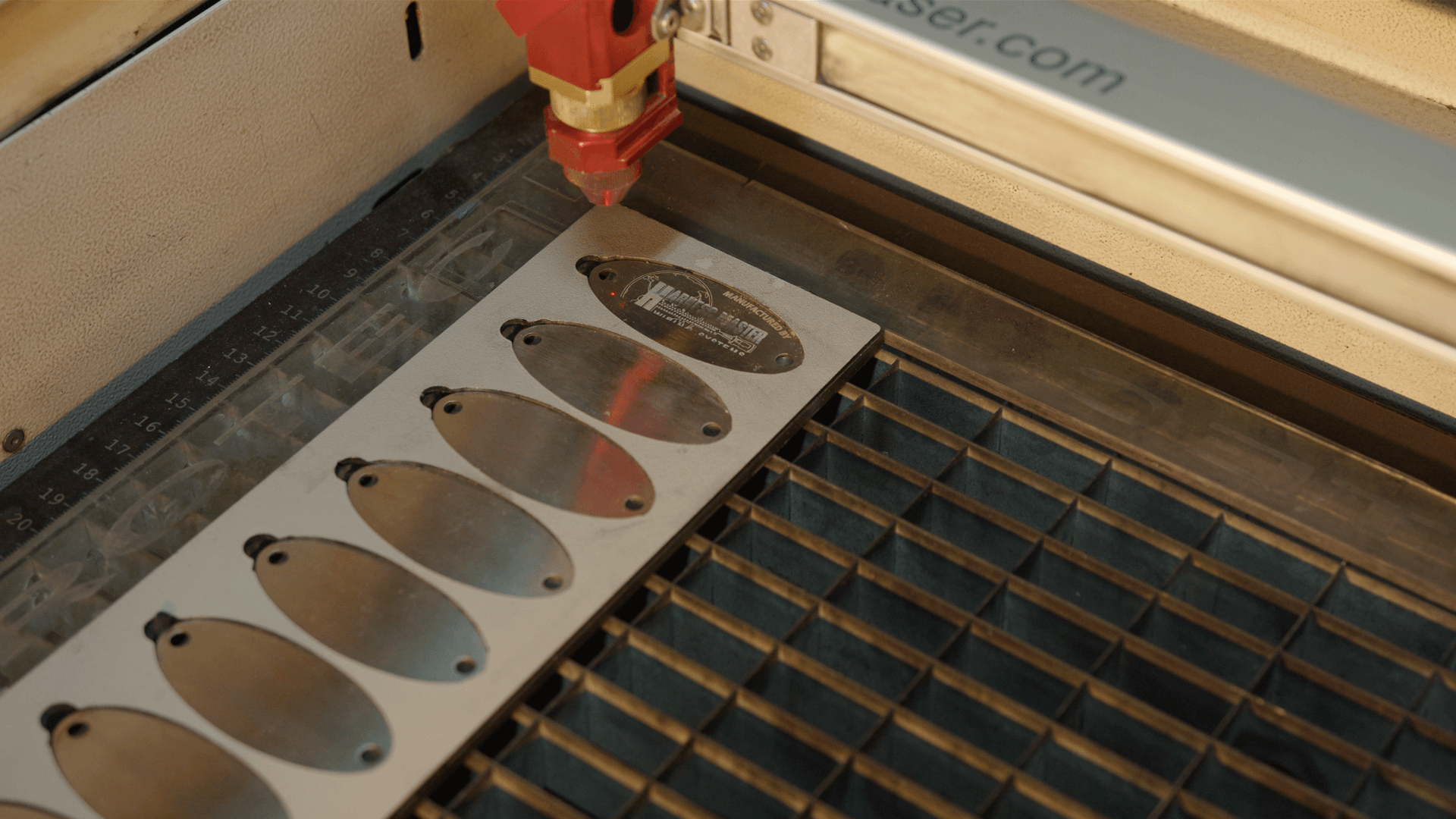

Over the years our reputation has supported our expansion into new products and services. Put simply, our customers continually ask us to do more and to expand our offering. Our vertically integrated approach offers a unique combination of innovation, problem-solving skills and world-class ISO 9001:2008 certified manufacturing facilities. Today, we are proud to say we are more than just a wiring harness manufacturer. We are now a solutions provider. Our capabilities span across our three divisions, Products, Engineering and Manufacturing.

Partnering with You

As the world keeps growing and changing, those who shape society and build infrastructure need reliable partners. For over 15 years, HMWS has been by your side, providing quality, dependability, knowledge, and support. By using new manufacturing and technology, we work with you to create solutions for a sustainable future. In this future, people, businesses, and our planet can thrive together.